Equipped for any welding task

To prevent exposure to soiling in the welding booth, both EWM Titan XQ 400 puls welding machines are located behind the rear panel of the booth. With its large repertoire of welding programs and potential uses, the Titan XQ is perfect for the diverse applications of a contract manufacturer. The robot controls are located between the two welding machines, and the drums with the filler material are just beside the machines. These drums only have to be replaced about every three weeks, which makes a long period of welding possible. Additional drives ensure the reliable and consistent transport of the material to the welding torch, despite the long distance that has to be covered.

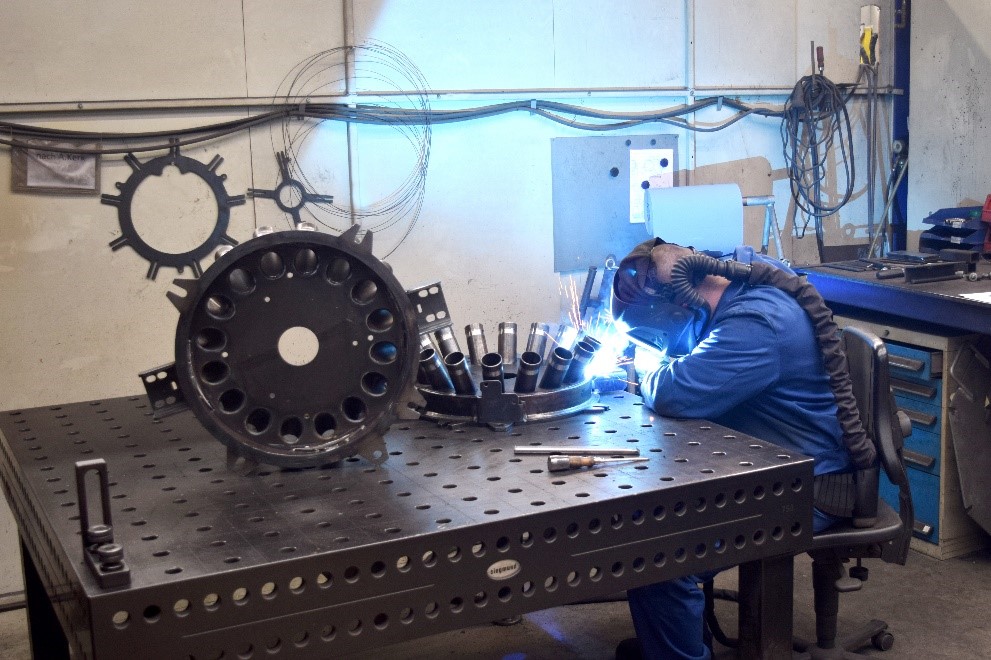

Countering the shortage of skilled workers

The shortage of skilled workers is significantly affecting welding companies at the moment. This makes it all the more important to break new ground and find alternatives, just like Finsterle GmbH have done. “I can have untrained employees insert parts and start the welding process with the robot,” explained Thomas Finsterle. Welders handle special one-off components and small batch sizes, as these tasks require a great deal of specialist knowledge. Thanks to the new robot cell, the Finsterle brothers are able to meet the latest challenges in the labour market.