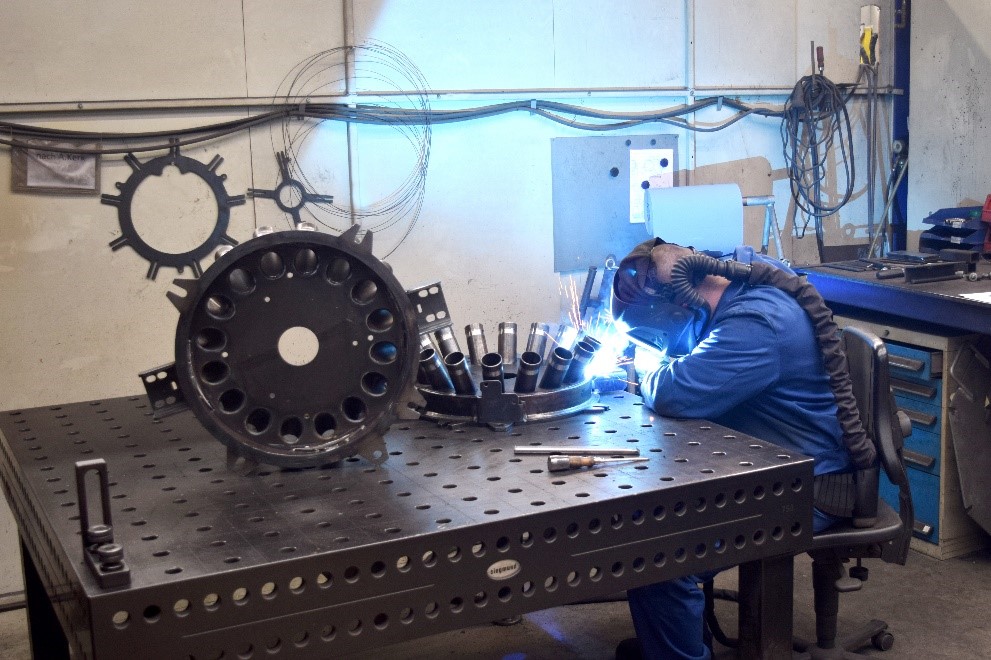

MST / Hi-Spec Manufacturing produces largest dredger and Face Shovel buckets in UK using EWM equipment

The challenge

One cubic metre of natural rock weighs around two tonnes – an MST bucket can carry up to five cubic metres without even breaking a sweat. Of course, this can be particularly demanding on the dredger and its power, as well as the bucket itself. The use of wear-resistant steels as a material choice and for the welding consumables is common. Speed and high quality are in high demand to ensure that the buckets can be quickly put back into action and avoid machine downtimes for the expensive dredgers. However, repairs to the original buckets shouldn’t just achieve the same quality – they should aim to exceed it. To do so, high-quality, reliable consumables and perfectly tailored procedures are key.

The solution

From welding machines and a wide variety of welding consumables to bespoke welding torches – EWM’s extensive range makes it the perfect partner for MST Parts Group. To ensure successful repairs, material quality is fundamental when it comes to processing wear-resistant steels such as S355, Weldox and all Hardox materials. A reliable product can only be manufactured by optimising the use of materials and implementing coordinated, monitored procedures. The quick delivery of consumables and EWM’s reliable equipment are both significant factors for MST Parts Group when it comes to successfully processing its customers’ enquiries.

The success

It’s not just MST’s customers who are thrilled with the welding results. The EWM products’ reliability was quickly noticed by MST, too. Thanks to their robust design, EWM products mean no more repair invoices for welding machines – costs that the company had become accustomed to in the past. The machines’ increased efficiency also significantly reduced the company’s hourly operating costs. What’s more, if there are ever any questions, EWM technicians are always on hand to provide help and advice.